This unit machine is special design for packaging liquid& sauces product into plastic bag .The machine have the function of automatic bag forming, Liquid product measuring and filling .With optional function of exhausting the air inside the bag and then sealing the bag .The machine also have color ribbon for date printer for coding of expiry date and production date.Widely use for packaging different liquid and paste product.

1, ZL520 vertical bag forming filling sealing Packaging machine

The whole machine made by Stainless Steel 304. This machine equipped with bag-making, cutting, code printing, etc. Siemens PLC and Touch Screen,Panasonic servo motor, Japanese Photo Sensor , Korean Air valve, etc. .The film pulling system adopted servo motor driving making speed faster.

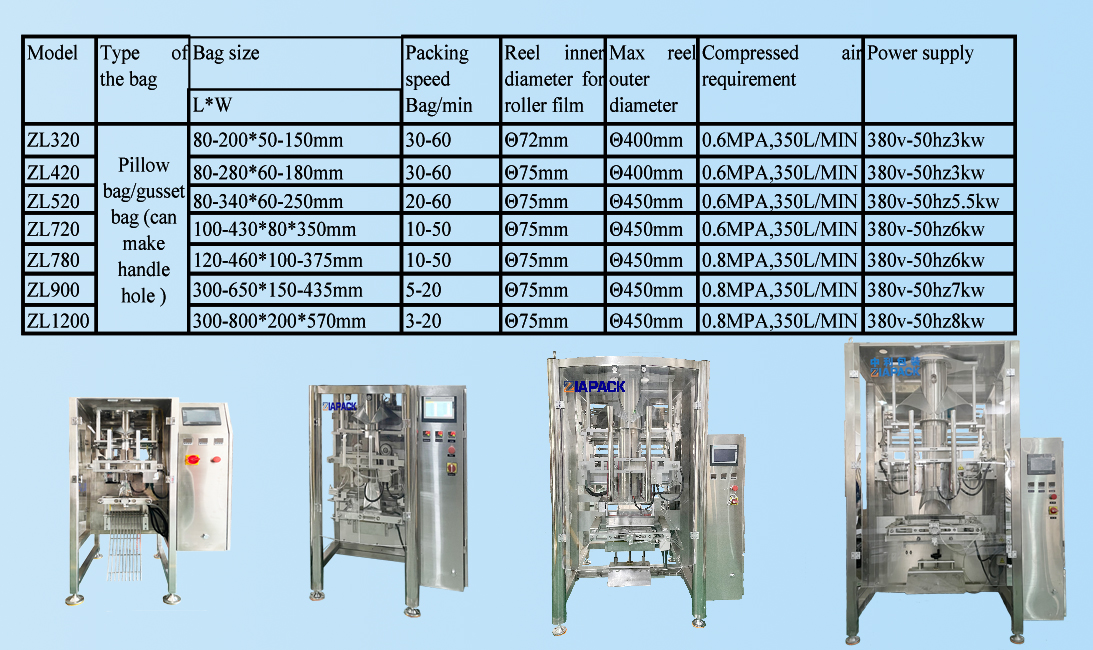

技術參數:

Weighing Range: 1000-2000g

Packaging Speed: 20-40 bags/min

Bag size: (80-360)*(100-250) mm (L*W)

壓縮空氣需求:0.6Mpa 0.65m3/min

Reel outer diameter: 400mm

芯內徑:75mm

Machine weight: 800kg

Power source: 5.5kW 380V±10% 50Hz

主要特點及特色:

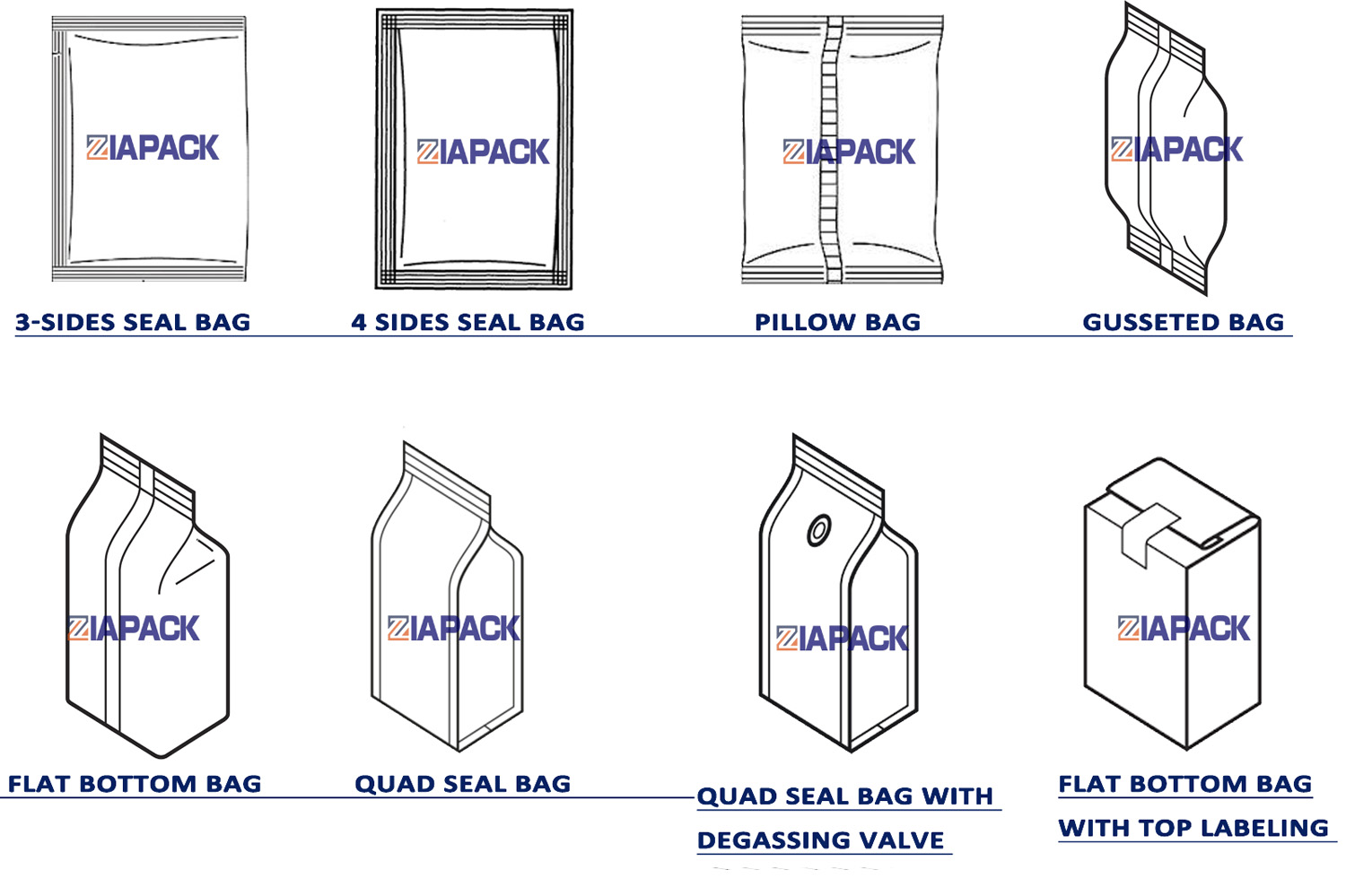

A wide range of pouches: Pillow and Gusset pouches.

High speed: 20-50 bags/min

操作方便:PLC控制器和彩色觸控螢幕,觸控螢幕上顯示故障。

易於調整:僅需約10分鐘即可更換不同的袋子。

頻率控制:速度可在範圍內通過頻率轉換進行調節。

高自動化:在稱重和包裝過程中無人值守,故障時機器自動報警。

安全衛生:

沒有膠片,機器會報警。

機器報警並在氣壓不足時停止。

安全開關,安全開關,機器報警和安全防護裝置打開時停止的安全防護裝置。

衛生結構,產品接觸部位均採用sus304不銹鋼。

Bag type

2,ZLB100 Piston pump with hopper

特徵

Standard with Airtac Piston.

All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

Suit for Viscous Liquid Model with stainless steel product hopper

Operated by foot pedal switcher or matching with full automatic packaging machine

With Anti-leaking system

Quick release nozzle and feed pipe

Technical parameter :

Filling range: 50-500 ML

Power supply: 220V 50HZ

Total power Power: 1650W

Heating power:1500W

Temperature range:20-90℃

Weight: 55kg

Hopper capacity: 30L

Air pressure: 0.4-0.6mpa

Working mode: need to be equipped with a power supply and air compressor

Machine material: case 201 stainless steel, material contact part is 304 stainless steel

填充精度:±1%

Filling efficiency: 0-25 bottles /H

Packing size:96*36*36cm (machine) + 60*54*81cm(hopper)