Machine details information

介紹 :This machine unit are design for packing two type different material mix into one bag .Whole machine unit including one set ZL520 vertical bag forming filling and sealing machine ,two sets ZL10-2.5L multi-heads weighing machine ,two sets incline conveyor ,This machine are widely use for packing small parts like hard ware,mix nuts or so on

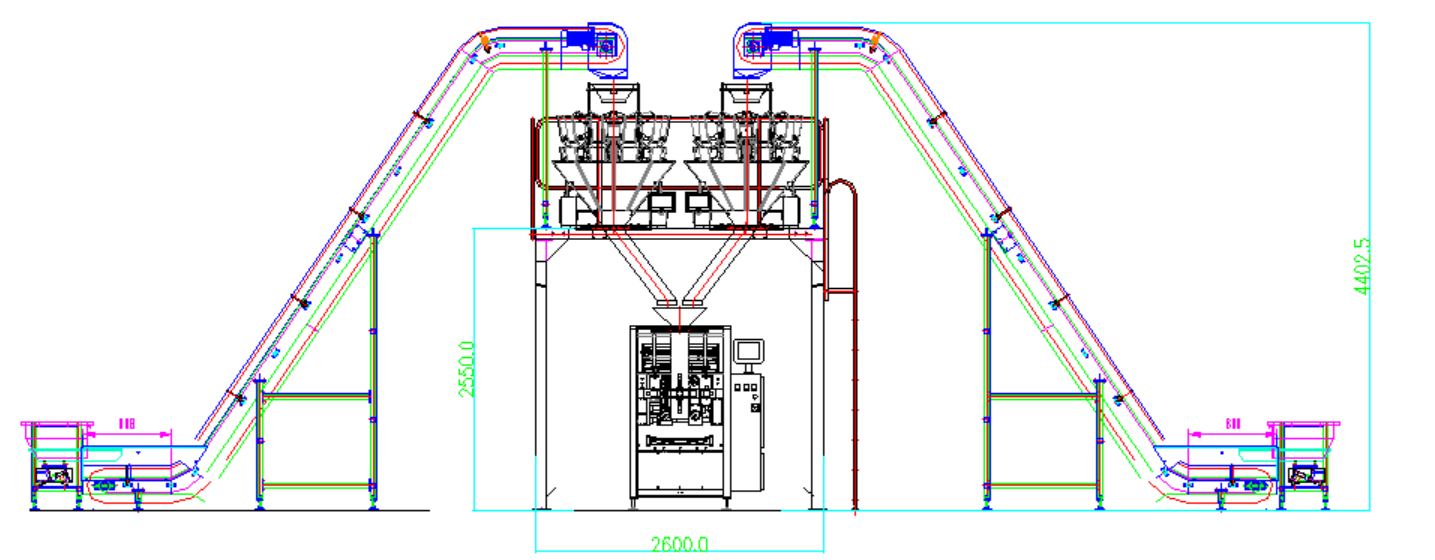

Layout of whole machine unit :

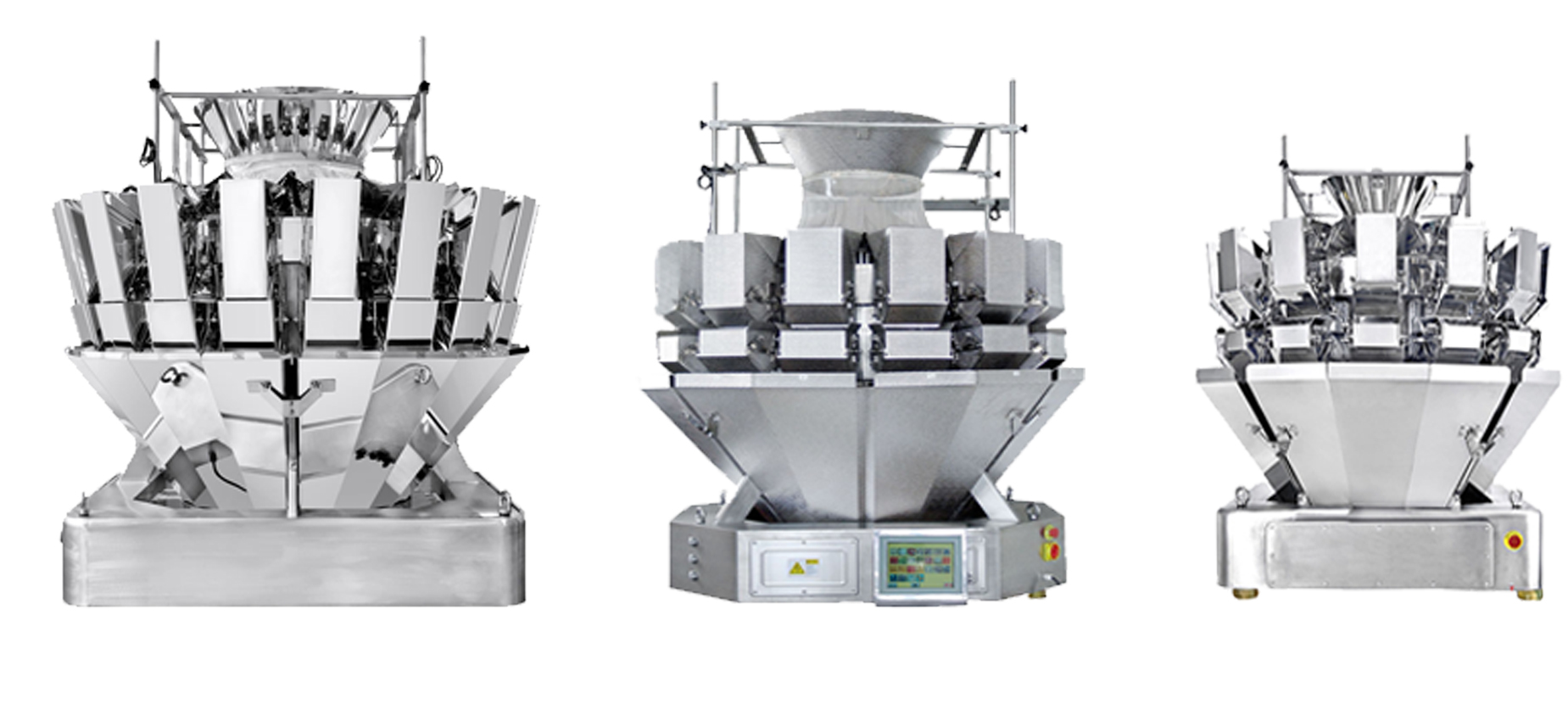

1,ZL10-2.5L Multi-heads weighing machine

應用:

All kinds of grains and solids, like candy, nuts, raisins, peanuts, melon seeds, nuts, potato chips, chocolate, biscuits and so on.

主要特點:

* Amplitude can be adjusted freely and individually in running status, more friendly HMI.

* Multi-language operating interface.

* Mouse, USB and SD card compatible with touch screen.

* Instant display of the weigh hopper

特殊功能:

* Modular electronic system makes maintenance easier and at lowest cost

* AD card are inter-changeable ,easy to be replaced ;

* Different authority managements, more user- friendly

* HMI can be upgraded by U disk

* Innovative Siemens PLC control system applied in the weigher and it makes machine more stable and low fault rate. Program update is much easier.

* Application software can be upgraded by memory card.

* Ethernet is available

產品規格

| 模型 | ZL10-2.5L |

| Max. Cap.(g) | 10-500g |

| Weighing Accuracy | 0.1-1.5g |

| Weighing speed | 30-80WPM |

| Hopper Capacity | 2500ml |

| 控制系統 | MCU |

| Operation Panel | 7 inch touch screen |

| 電源 | AC220V ±10%, 50Hz(60Hz) |

ZL520 Model vertical bag forming filling sealing machine

介紹 :

The unit of machine is especially developed for snack food packaging ,This machine can independently complete the weighting bag making, filling (air filling or exhausting), sealing, hole punching , code printing, and bag counting etc. It including cup filling system, packaging machine and elevator .

Technical parameter:

Weighing Range: 100-1000g

Packaging Speed: 30-40 bags/min

Bag size: (100-340)*(80-260)mm(L*W)

壓縮空氣需求:0.6Mpa 0.65m3/min

Reel outer diameter: 400mm

芯內徑:75mm

Machine weight: 800kg

Power source: 5.5kW 380V±10% 50Hz

Work Flow Chart:

Auto Weighing → Film Pulling → Date Printing → Filling → Bag Forming → Bag Sealing → Finished Product output